Ever held a perfectly balanced knife and wondered what makes it so special? It’s not just the sharp edge; it’s the metal it’s made from. Choosing the right metal for a knife can feel like navigating a maze. You want something strong enough to chop vegetables without chipping, sharp enough to slice paper-thin, and tough enough to handle tough jobs. But with so many types of steel and alloys out there, where do you even start?

This confusion is a common pain point for anyone looking to craft their own knife or simply understand what makes a good one. You might worry about spending time and money on the wrong material, only to end up with a blade that dulls quickly or breaks easily. It’s frustrating when your hard work doesn’t pay off because of a simple material choice.

But don’t worry! By the end of this post, you’ll understand the key differences between popular knife metals. We’ll break down what makes each one tick, so you can pick the perfect metal for your next project. Let’s dive into the fascinating world of knife steels and discover what makes a blade truly exceptional.

Our Top 5 Metal To Make A Knife Recommendations at a Glance

Top 5 Metal To Make A Knife Detailed Reviews

1. How to Make Knives

Rating: 8.9/10

This “How to Make Knives” guide is a fascinating look into a traditional craft. It explores the process of transforming raw materials into functional tools. You’ll learn about different metals and how to shape them. It also covers important safety steps. This guide is for anyone curious about blacksmithing or knife making.

What We Like:

- It offers a clear step-by-step process.

- It introduces basic knife-making techniques.

- It sparks creativity and hands-on learning.

- It provides insight into a historical skill.

What Could Be Improved:

- It lacks specific material recommendations.

- It doesn’t detail specialized tool requirements.

- More visual aids would be helpful.

- Advanced techniques are not covered.

This guide is a good starting point for aspiring knife makers. It lays the groundwork for understanding the basics of this intricate art.

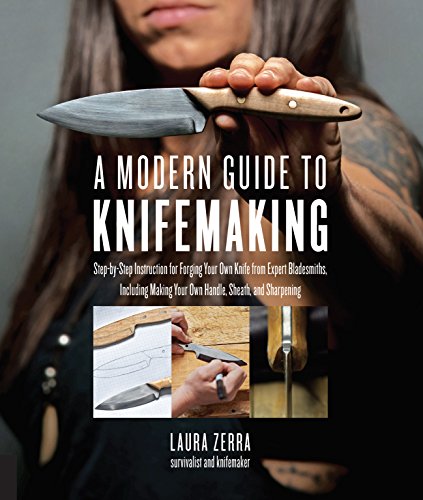

2. A Modern Guide to Knifemaking: Step-by-step instruction for forging your own knife from expert bladesmiths

Rating: 8.6/10

Ever dreamed of crafting your very own knife? ‘A Modern Guide to Knifemaking’ makes that dream a reality. This book guides you through every step. You’ll learn to forge your own blade from scratch. Expert bladesmiths share their knowledge. You’ll also discover how to create a comfortable handle and a protective sheath. Finally, you’ll master the art of sharpening your creation. It’s a complete guide for anyone wanting to make a functional, beautiful knife.

What We Like:

- Clear, step-by-step instructions are easy to follow.

- Covers all aspects of knifemaking, from forging to sharpening.

- Expert advice from experienced bladesmiths builds confidence.

- You learn to make a custom handle and sheath.

- Empowers you to create a unique, handmade tool.

What Could Be Improved:

- May require purchasing additional tools and materials not included in the book.

- Some advanced techniques might need further research for absolute beginners.

This book is an excellent resource for aspiring bladesmiths. It provides the knowledge and direction to forge your own unique knife.

3. Custom Knifemaking (10 Projects from a Master Craftsman)

Rating: 9.1/10

Ready to forge your own path to custom knifemaking? This book, “Custom Knifemaking (10 Projects from a Master Craftsman),” is your guide. It’s a used book, but it’s in good condition, meaning you can still learn a lot from it. You’ll find ten different projects inside, showing you how to create your own unique knives. A master craftsman shares their secrets, so you’ll be learning from the best. This book can help you turn your ideas into sharp, beautiful tools.

What We Like:

- Learn from a master craftsman, gaining valuable skills.

- Ten different projects offer variety and learning opportunities.

- The book is in good condition, making it a great value.

- It’s a fantastic way to get started in a rewarding hobby.

What Could Be Improved:

- As a used book, it might have some minor wear and tear.

- Some projects might require tools you don’t already own.

This book is a fantastic resource for anyone eager to explore the art of knifemaking. It offers a clear path to creating your own custom blades.

4. Blacksmithing For Beginners: 21 Tips On How to Make A Forge and Start Hammering Metal: (Blacksmithing

Rating: 8.9/10

Ready to get your hands dirty and shape metal like the pros? “Blacksmithing For Beginners: 21 Tips On How to Make A Forge and Start Hammering Metal” is your ticket into the exciting world of blacksmithing. This guide is packed with practical advice to help you build your very own forge and start hammering away. Whether you dream of making your first knife or just want to try a cool new skill, this book has you covered. It breaks down everything you need to know in an easy-to-understand way, making blacksmithing accessible for everyone.

What We Like:

- It offers clear, step-by-step instructions for building a forge.

- The 21 tips are super helpful for absolute beginners.

- It covers the basics of hammering metal effectively.

- The guide makes a complex skill seem achievable.

- It’s a great starting point for DIY projects.

What Could Be Improved:

- More detailed safety guidelines could be included.

- Visual aids like diagrams or pictures would be beneficial.

- A section on troubleshooting common beginner issues would be useful.

This guide truly empowers beginners to take their first steps in blacksmithing. It’s a fantastic resource for anyone looking to learn this ancient craft.

5. SOGO KNIVES Damascus Knife Making Kit DIY Handmade Knife Kit Includes Knife Blank Knife Steel Blade

Rating: 9.3/10

Unleash your inner artisan with the SOGO KNIVES Damascus Knife Making Kit. This all-in-one package provides everything you need to create your very own unique, handmade Damascus steel knife. From the striking blade to the genuine leather sheath and handle scales, this kit is designed for both beginners and experienced crafters looking to bring their dream knife to life.

What We Like:

- Complete Kit: Everything you need is in one box, including the Damascus steel blade, pins, handle scales, and a real leather sheath.

- Premium Steel: Made with 1095 and 15N20 steel, known for their durability and ability to hold a sharp edge, offering a hardness of 58-60 HRC.

- Unique Artistry: Each Damascus steel blade is one-of-a-kind, making your finished knife a truly special piece.

- High Quality: SOGO Knives focuses on careful craftsmanship and high-quality materials for excellent finishing.

- Satisfaction Guaranteed: The company offers a full refund if you’re not happy with your purchase.

What Could Be Improved:

- Handle Hole Variations: The placement and size of holes in the handle may require some adjustment with sandpaper.

- Pin Adjustment: Pins might be slightly larger than needed and may require sanding to fit the handle holes perfectly.

This kit is a fantastic way to experience the rewarding process of knife making. It’s a great gift for anyone who appreciates craftsmanship and unique, handmade items.

Choosing the Right Metal for Your Knife: A Buyer’s Guide

Making a knife can be a fun and rewarding project. But before you start, you need to pick the right metal. The metal you choose is super important. It affects how sharp your knife gets, how strong it is, and how well it holds an edge. Let’s dive into what makes a good knife metal.

1. Key Features to Look For

Sharpness and Edge Retention

You want a knife that can get really sharp. You also want it to stay sharp for a long time. Some metals are better at holding a sharp edge than others. This means you won’t have to sharpen your knife as often.

Strength and Durability

A good knife metal needs to be strong. It shouldn’t break or bend easily. Think about what you’ll use the knife for. If you’re doing tough jobs, you need a really strong metal. Durability means your knife will last a long time.

Corrosion Resistance

Some metals can rust or get damaged by water and salt. You want a metal that won’t rust easily. This keeps your knife looking good and working well, even if it gets wet.

2. Important Materials

High Carbon Steel

This is a very popular choice for knife making. It has a good amount of carbon, which makes it hard. This means it can get very sharp and hold that sharpness well. However, it can rust if you don’t take care of it.

Stainless Steel

Stainless steel has chromium added to it. This makes it very resistant to rust. It’s a good choice if you want a low-maintenance knife. Some stainless steels can be made very hard, but others might not hold an edge as long as high carbon steel.

Tool Steel

Tool steels are designed for tough jobs. They are very hard and strong. Many tool steels can hold an edge for a long time. Some tool steels can be a bit harder to work with when you’re making the knife.

3. Factors That Improve or Reduce Quality

Heat Treatment

How the metal is heated and cooled is called heat treatment. This process makes a huge difference in the metal’s strength and how well it holds an edge. Good heat treatment makes a good metal great. Bad heat treatment can ruin even the best metal.

Alloying Elements

Adding other metals, like chromium, nickel, or vanadium, changes the properties of the steel. These additions can make the steel harder, tougher, or more resistant to rust. The right mix of these elements is important for quality.

Manufacturing Process

How the metal is made matters. Metals made with careful processes are usually of higher quality. This means they have fewer imperfections and are more consistent.

4. User Experience and Use Cases

Everyday Carry (EDC) Knives

For knives you carry every day, stainless steel is often preferred because of its rust resistance. A good balance of sharpness and durability is key.

Kitchen Knives

Kitchen knives need to be very sharp and hold that sharpness. High carbon steel is a common choice here. Easy cleaning and resistance to food acids are also important.

Outdoor and Survival Knives

These knives often face tough conditions. They need to be strong, durable, and able to hold a sharp edge for a long time. High carbon steel and some tougher tool steels are good options.

Collecting and Display Knives

For knives that are more for looks, the aesthetic appeal and resistance to tarnishing might be more important. High-quality stainless steels can be a good choice.

Frequently Asked Questions (FAQ)

Q: What is the best metal for a beginner knife maker?

A: For beginners, high carbon steel like 1075 or 1084 is often recommended. It’s easier to heat treat and work with compared to some other steels.

Q: Will my knife rust if I use stainless steel?

A: While stainless steel is much more resistant to rust than carbon steel, it can still rust under certain conditions, especially if exposed to salt or harsh chemicals for long periods without cleaning.

Q: How does the thickness of the metal affect the knife?

A: Thicker metal generally makes a stronger, more robust knife that is less likely to bend. Thinner metal can be lighter and allow for a finer, sharper edge, but it might be less durable for heavy tasks.

Q: Is it better to have a hard knife or a tough knife?

A: It’s a balance. Harder steel holds a sharper edge for longer. Tougher steel is less likely to chip or break. The best knife metal has a good mix of both.

Q: What is “temper” in knife making?

A: Tempering is a heat treatment process done after hardening. It reduces brittleness and increases toughness, making the knife more usable without sacrificing too much hardness.

Q: Can I use scrap metal to make a knife?

A: While it’s possible, using scrap metal can be unpredictable. The exact composition and heat treatment properties of scrap metal are often unknown, which can lead to poor performance or difficulty in making the knife.

Q: What is meant by “grain structure” in steel?

A: Grain structure refers to the arrangement of the metal’s crystals. A fine, uniform grain structure generally leads to better strength, toughness, and edge retention.

Q: How does the ” Rockwell hardness” scale relate to knife steel?

A: Rockwell hardness measures a metal’s resistance to indentation. For knives, a higher Rockwell number usually means the steel is harder and will hold an edge longer, but it can also make the steel more brittle.

Q: What are some common alloying elements and what do they do?

A: Chromium adds corrosion resistance. Vanadium and tungsten can increase hardness and wear resistance. Molybdenum improves toughness and strength at high temperatures.

Q: Is it worth paying more for premium knife steel?

A: For knives that will see heavy use or require specific performance characteristics like extreme edge retention or corrosion resistance, investing in premium steel can be very worthwhile.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.